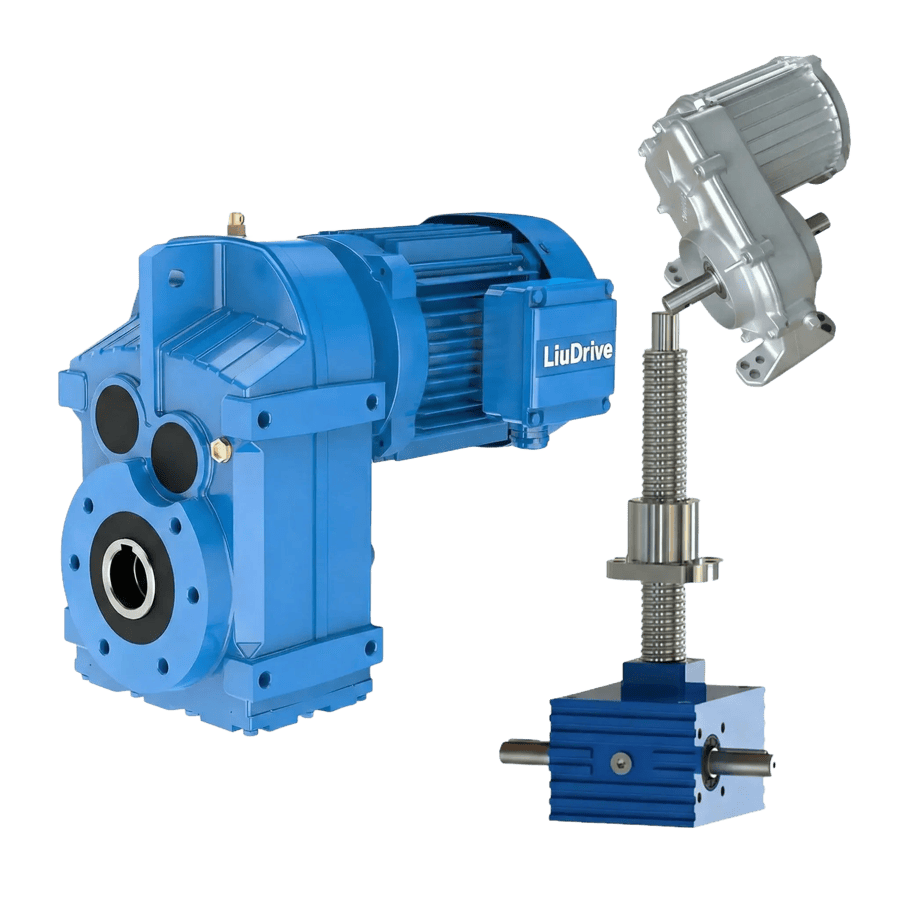

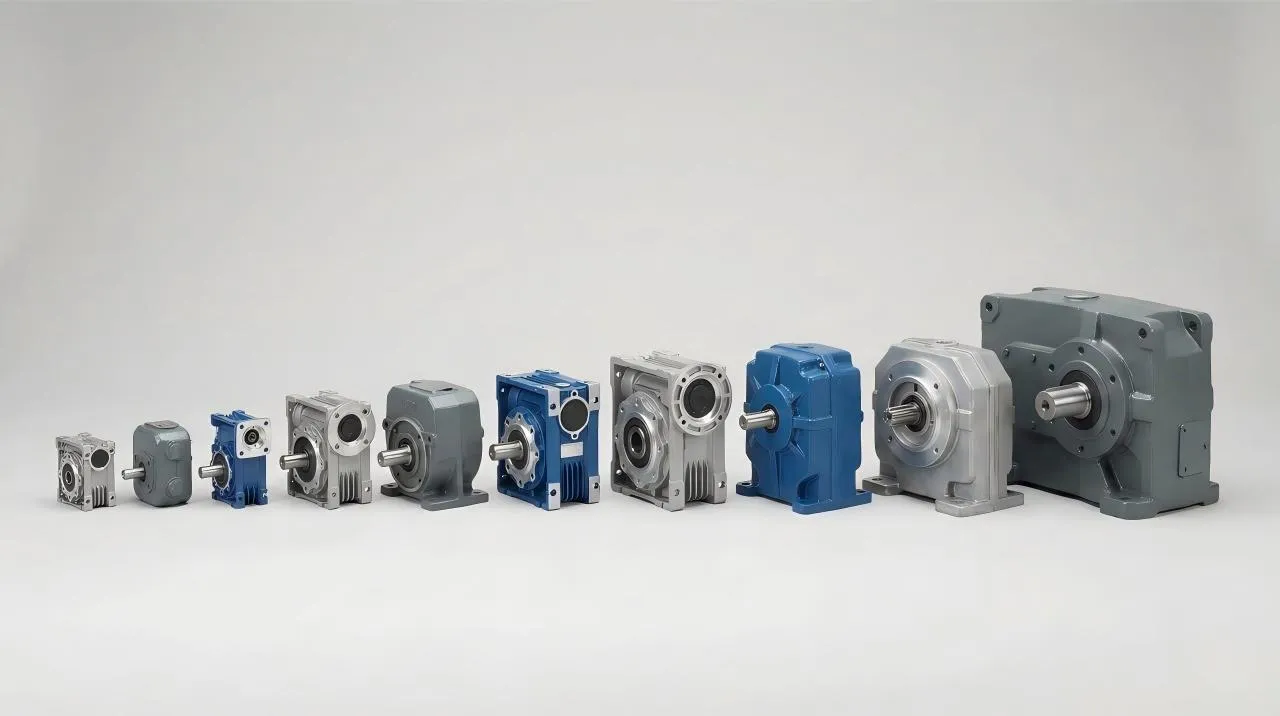

We manufacture a wide range of gearboxes, gearmotors, and screw jacks as replacements for globally recognized brands.

Backed by a veteran engineering team with nearly four decades of hands-on transmission experience.

Decades of exposure to complex OEM digital models and CAD data ensure geometric precision.

Engineered to be functionally equivalent and a perfect drop-in fit without modifications.

We turn your samples, drawings and ideas into engineered power transmission products. From 1:1 drop-in replacement of existing gearboxes to custom screw jacks and irrigation gearboxes, we design, validate and produce parts that fit right the first time.

We support a wide range of existing machine models and brands. In many cases, our power transmission products can drop in 1:1, with no redesign of your equipment needed.Suitable Systems: Valley, Zimmatic, Reinke, T-L, Lockwood, Pierce, Olson, AgSense-ready models, and other major OEM platforms.

Designed to match the interfaces and duty cycles of widely used international brands, our gearboxes, gearmotors and screw jacks drop easily into existing machinery.

Controlled materials and machining deliver stable torque, reliable sealing and long service life.

Compact power transmission gearboxes for conveyors, mixers and other OEM machinery.

Worm gear screw jacks for lifting, positioning and precise adjustment in mechanical systems.

Gearboxes for center pivot and lateral move irrigation systems in agricultural fields.

With 38 years in power transmission, we supply gearboxes, gearmotors and screw jacks for OEMs, distributors and equipment builders worldwide. By combining 1:1 replacement of international brands, reverse engineering and an integrated sourcing network across China, we serve as your long-term engineering and supply partner.

We have spent 38 years focused exclusively on gearboxes, gearmotors and screw jacks.

Share the brand and model; we build a 1:1 compatible unit for your existing machine.

Nameplate photo, key dimensions or an old sample are often sufficient to reproduce the part.

We keep parameters and drawings for many global brands, enabling fast and accurate matching.

Within 48 hours we confirm stock or production, with standard lead times from 7 to 40 days.

Most projects start from breakdowns or urgent replacements. We accept small quantities to keep your operations running.

We handle single-unit replacements and small batches that OEM brands often refuse or price very high.

We know which factories are best for each product type and match your project to the right producer.

We support overseas distributors by handling technical matching and supplying compatible units ready for resale.

4,000+

38+

48 Hours

7–40 days

Our own large factory with advanced machining and assembly lines is backed by a family network of five specialized plants. Together, we cover multiple power transmission product lines and give you flexibility in volume, precision and cost level.

Whether you have digital specs, paper drawings or a worn original component, we can reverse-engineer and manufacture a 1:1 replacement – and even optimize materials and key parameters so it performs better than the original.

Share your models, parameters or basic specs, and we turn them into real gearboxes, screw jacks or irrigation gearboxes that fit your equipment and load conditions.

Whether you have paper drawings, a nameplate photo or a worn original unit, we can reverse-engineer the design and build a 1:1 compatible replacement for your machine.

When you want more than a simple copy, we can upgrade materials and key parameters to improve life, safety margins or efficiency while keeping installation dimensions unchanged.

We integrate our own factories with a network of specialized Chinese manufacturers for gearboxes, gearmotors and screw jacks, so you get the right production base instead of guessing from thousands of suppliers.

Talk directly with a power transmission specialist with 38 years of experience. We review your specs, failures and operating conditions, then recommend 1:1 replacements or upgrades to get your lines running again as fast as possible.

From your first inquiry to a running machine, the process is simple: share your specs or old parts, we check compatibility, manufacture and test the unit, then support your installation. Each step is designed to make sure what you receive really fits your equipment and keeps downtime to a minimum.

Explore our comprehensive range of OEM/ODM capabilities and how we can collaborate to bring your project to fruition with superior components designed for your unique specifications.

Our dedicated team is here to assist you, ensuring you have the right solutions to maximize your efficiency. Whether it's design queries or technical support, we're committed to providing exceptional service throughout your project’s lifecycle.

We check compatibility based on your data. If you send us the brand & model, nameplate photo, key dimensions (centre height, shaft diameter, flange size, bolt pattern) or CAD drawing, our engineers match the mounting interface, ratio and torque. For 1:1 replacements we keep all critical dimensions the same, so you can swap the unit without re-designing the machine.

At minimum we need:

Application (what machine / where it’s used)

Required ratio and output speed

Load or output torque / lifting load

Duty cycle (hours per day, starts per hour)

Mounting type and key dimensions

If it’s a replacement, a nameplate photo or old part photos are often enough for us to identify the right model.

Yes. With 38 years in power transmission, we have collected a large database of dimensions and parameters for many European and US brands. In most cases we can offer a fully compatible gearbox, screw jack or irrigation gearbox with the same mounting, ratio and performance, at a significantly lower total cost.

For standard models and common ratios, we can arrange production or shipment within 7–15 days after order confirmation. For customised designs the lead time is usually 15–40 days, depending on complexity and quantity. We can start from 1 piece per model, which is convenient for maintenance, retrofit and trial orders.

All units are manufactured on controlled production lines, with material traceability, critical dimension checks and 100% test run before shipment. If any problem occurs under normal use, our engineering team will analyse the cause and provide replacement parts or technical solutions according to the agreed warranty terms. We also support you with installation and maintenance advice to help avoid issues in the first place.

lashawn@liudrive.com

Shijiazhuang City, Hebei Province,China

Phone : +86 13731164555

Monday - Saturday 09.00 - 18.00

Share your model numbers, photos or key dimensions and we’ll help you check compatibility and prepare a quotation.

See our workshops, equipment and testing process in person. Leave your details and we’ll arrange a suitable visiting time for you.